Get connected with our experienced in-house team

With nearly 40 years in the business developing custom architectural exterior solutions, we’re confident that you’ll find your experience working with Cascade easy, enjoyable and rewarding, and encourage you to share your performance and visual criteria with us before writing a specification.

With each new project comes a unique set of performance criteria, structural requirements, sustainability goals, design vision, and other considerations, so don't hesitate to leverage our experience by collaborating throughout the design and specification process. Our in-house technical experts can quickly help you identify the optimal combination of material specifications and pre-engineered or custom attachment hardware to develop a system that meets or exceeds all project requirements to not only ensure reliable project delivery, but save you time in the process.

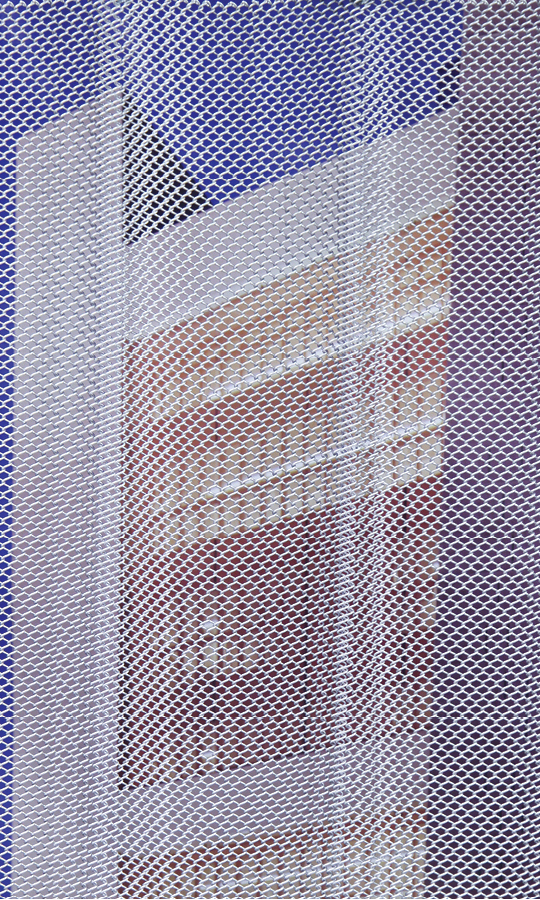

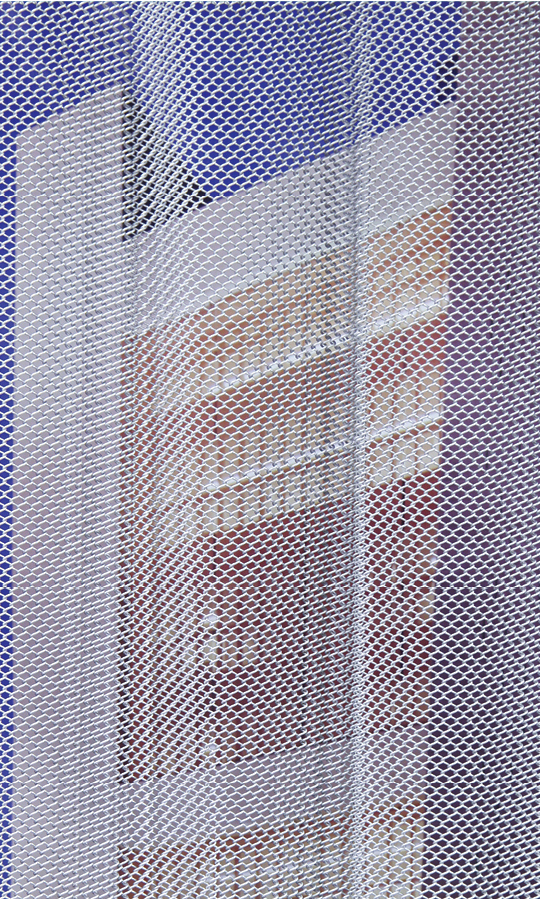

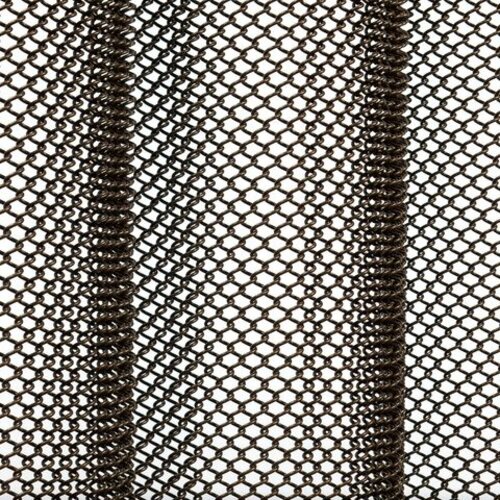

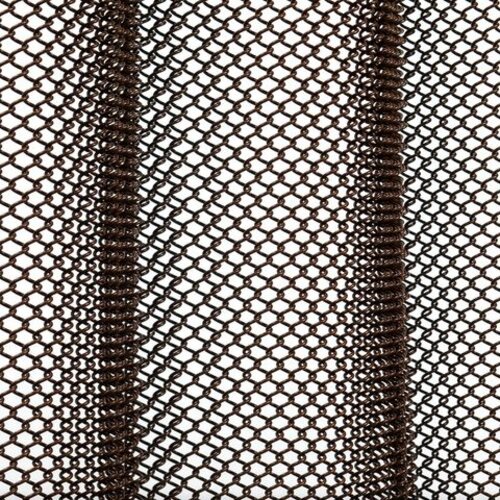

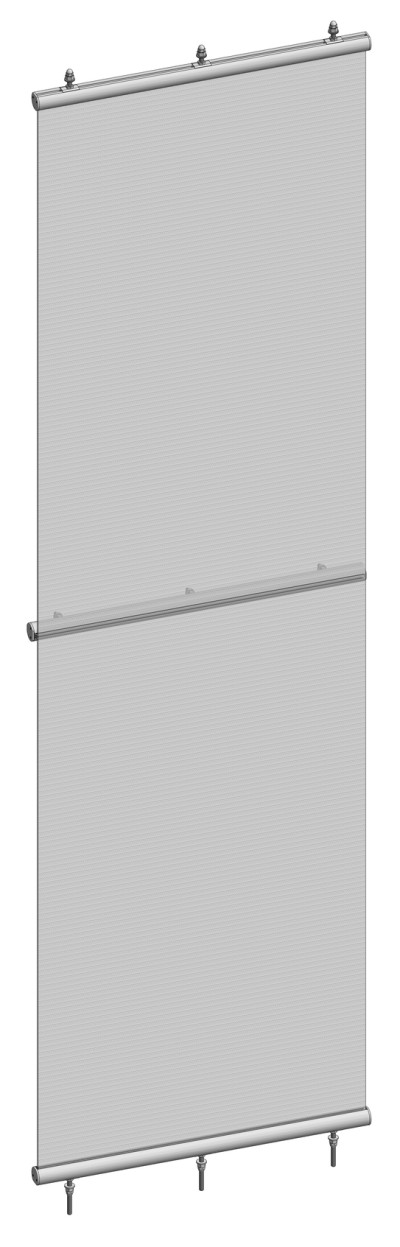

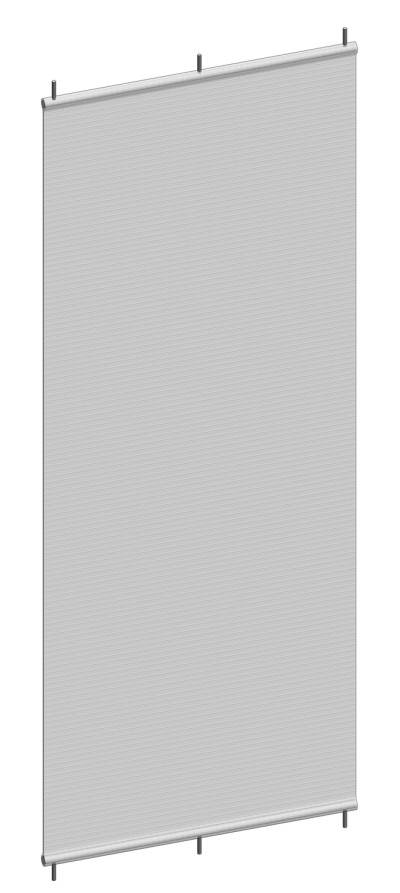

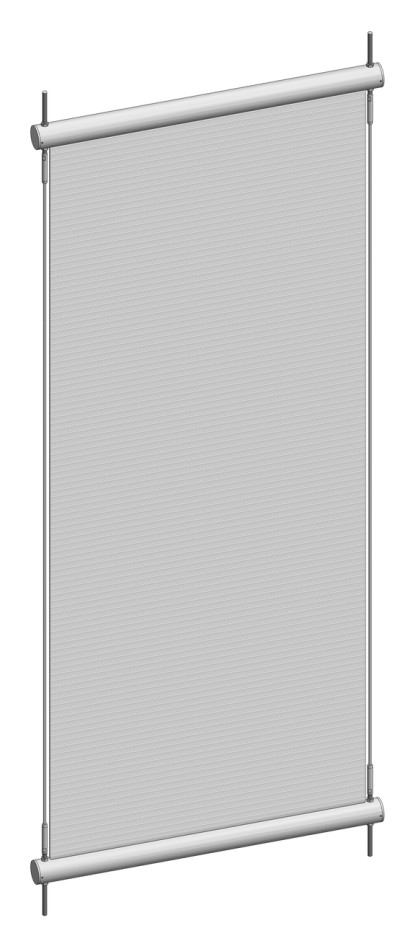

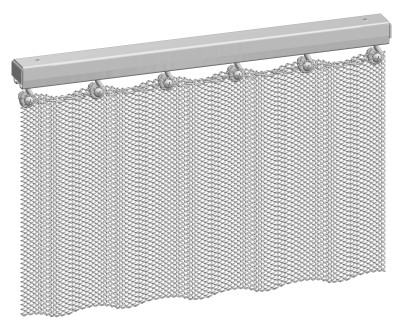

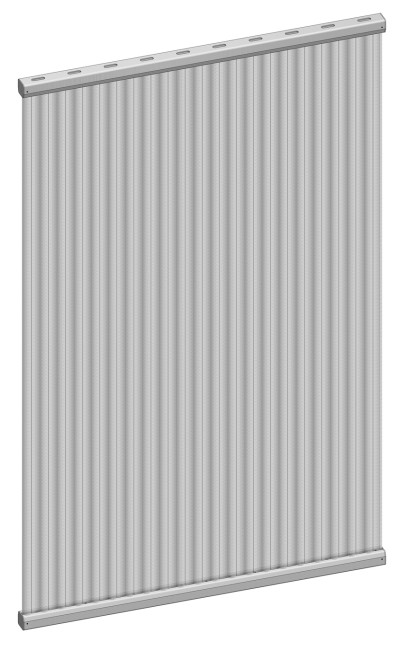

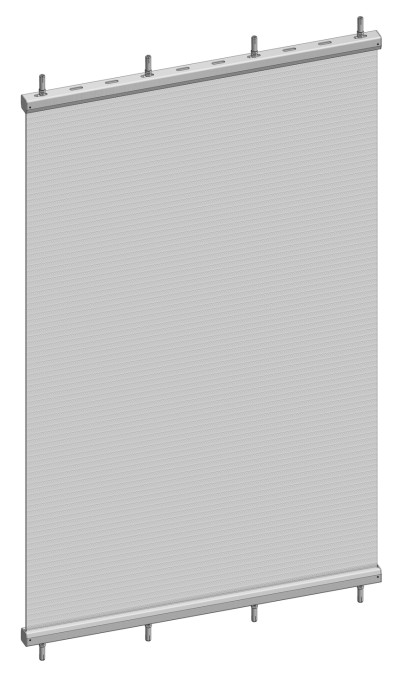

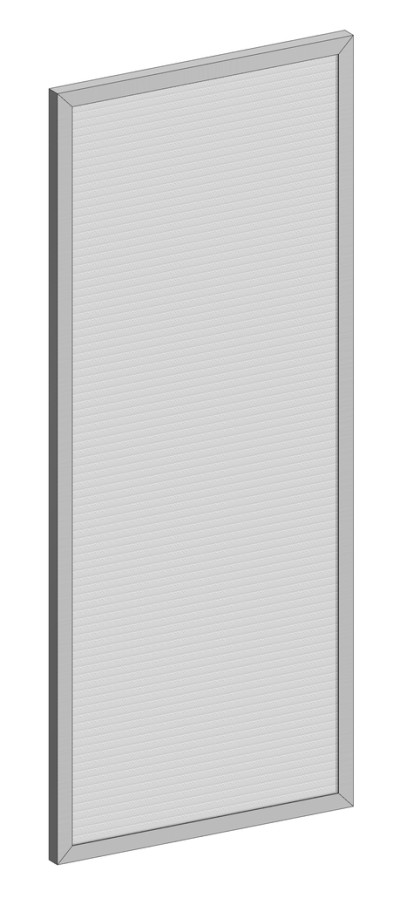

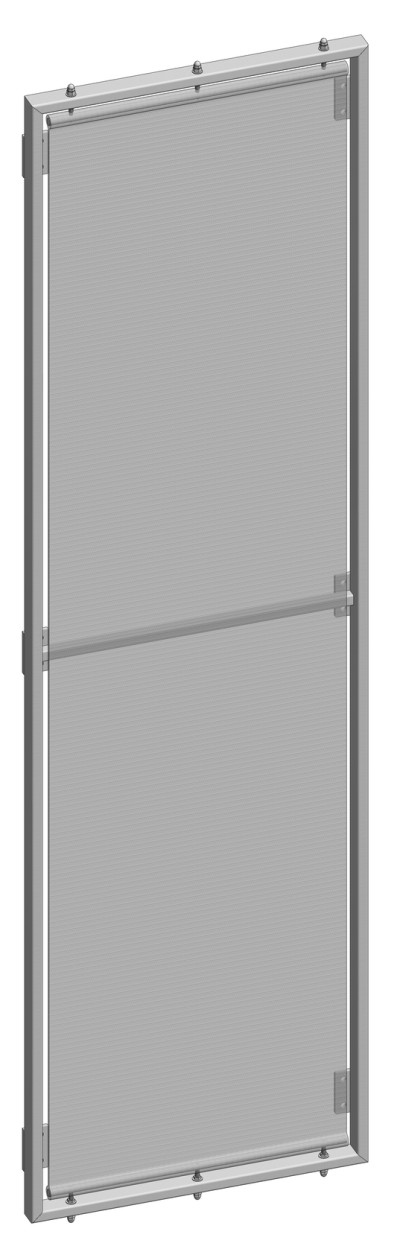

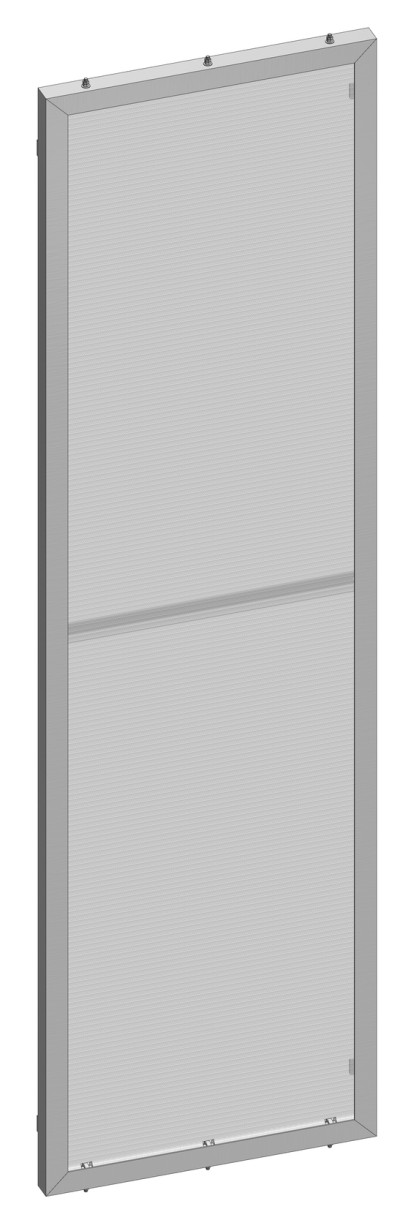

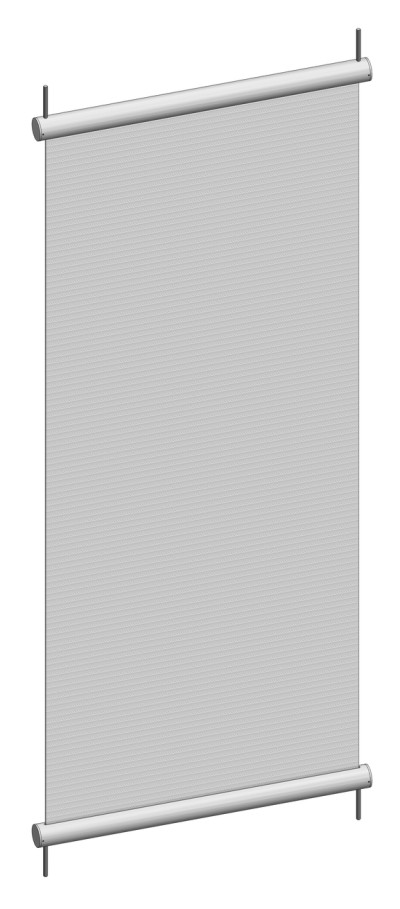

Fullness Options for Exterior Metal Mesh Drapery Applications

Fabricoil Coiled Wire Fabric Materials, Colors & Finishes for Exterior Applications

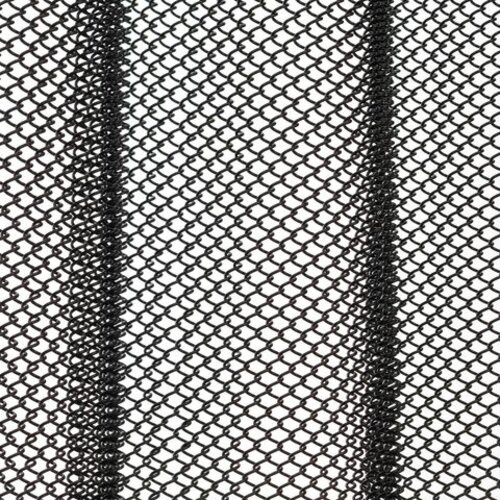

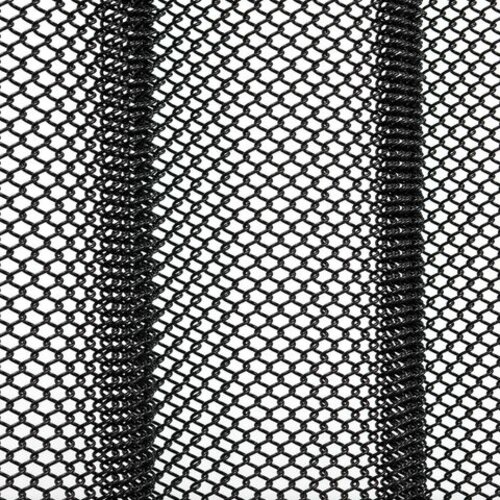

To deliver your design vision, Cascade Architectural offers high-performance protective coatings for Fabricoil® coiled wire fabric and its attachment systems to achieve your project’s functional and aesthetic requirements. Coatings are provided in a wide range of standard colors and finishes, and can also be specified in custom colors using your manufacturers paint codes or standard RAL color codes to match specific brand colors or to achieve a specific vision.

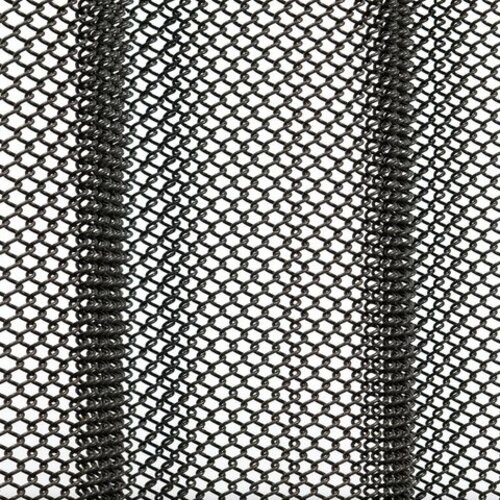

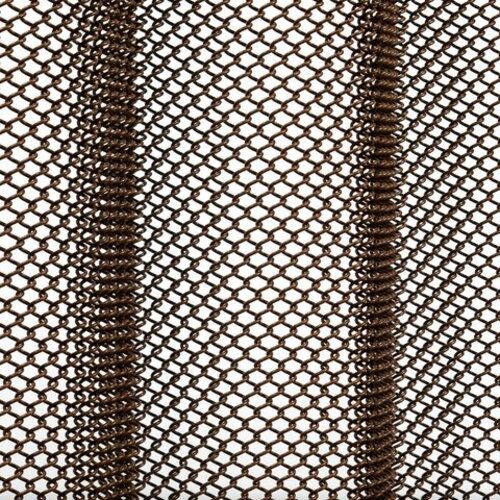

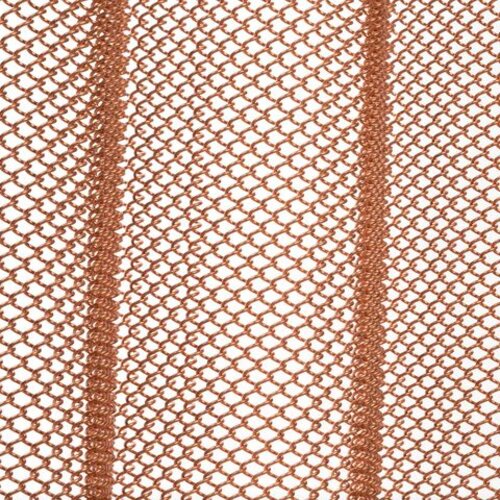

For maximum durability, Fabricoil® coiled wire fabric is typically powder-coated unless natural finishes are desired, but all standard powder coatings and base wire materials meet stringent Declare Living Building Challenge "Red List Free" requirements (labels available upon request). For a natural metal aesthetic, stainless steel and copper-clad steel coiled wire fabric can be left in its natural form. Left unfinished, copper-clad steel will slowly change to brownish hues over time and ultimately bear the classic bronze/grey/green patina for which copper is known.

For exterior applications, Cascade has conducted extensive successful salt-spray testing to ASTM G85 annex A5 test standards to 4,000 hours of exposure.

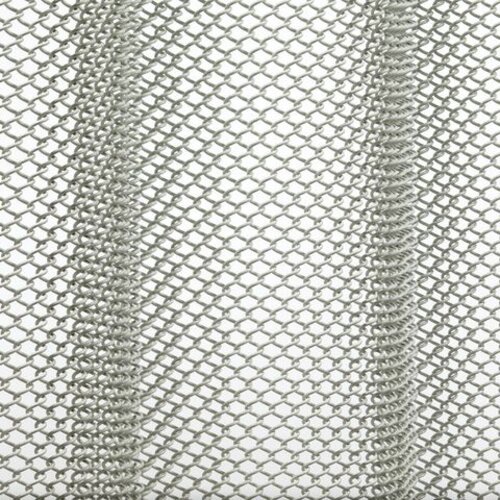

Fabricoil coiled wire fabric weaves come equipped with high-performance protective powder coatings or clear lacquer, or can be left uncoated for a more raw, natural appearance. Below are a list of raw materials used to create Fabricoil weaves, a guide to their finishes, and a look at a few of our standard powder coated finishes. Our team of experienced product specialists are ready to assist you in selecting the appropriate type of protective coating to bring your vision to life.

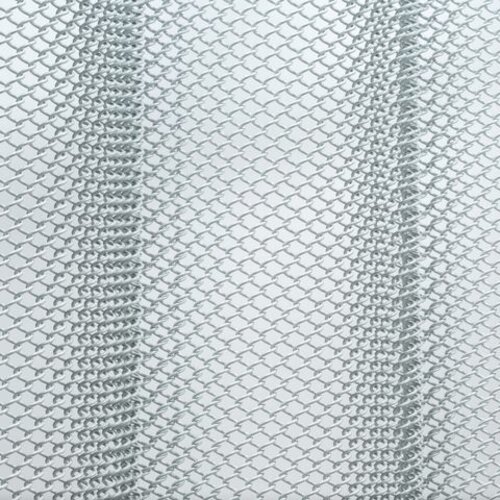

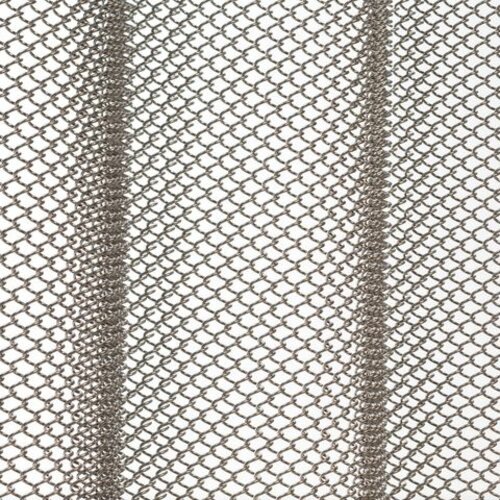

Aluminum

Aluminum 5056 – H18 Wire is an ideal material for our weaving process. Its ease of formability, high resistance to corrosion, excellent strength-to-weight ratio and its natural aesthetic qualities make aluminum wire the obvious choice for most applications. Our Aluminum Wire is very ductile-aiding to the weaving process, making it relatively cheap to manufacture. Being non-ferrous, the material does not discolor or deteriorate in most climates. Weighing almost 1/3-1/2 that of steel, Aluminum weaves can cover more area while adding minimal mass to its supports, again decreasing the overall cost. In its bare state, Aluminum Wire is light silver in appearance but can be coated any custom color. Additionally, our Aluminum wire can be polished to be more lustrous, called Brightened Aluminum. Aluminum is available in a wide variety of wire gauges.

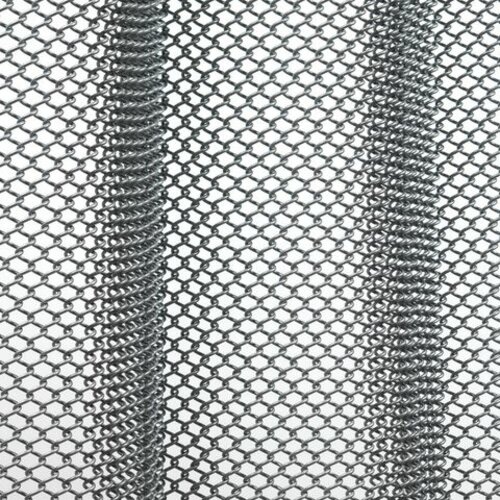

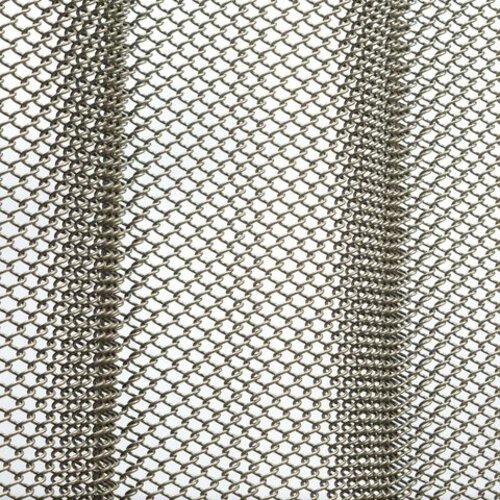

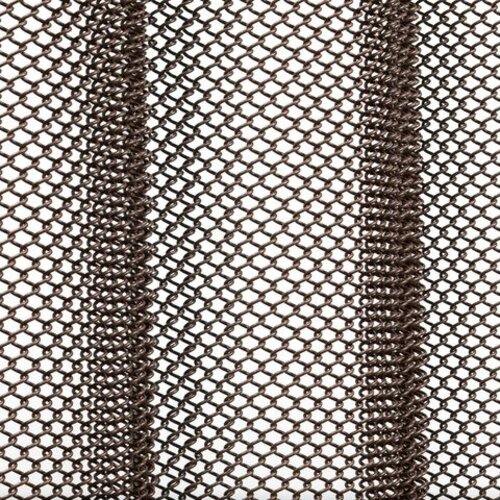

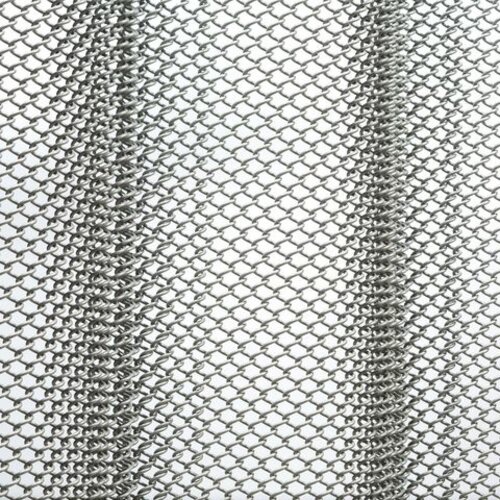

Stainless Steel Type 316

Stainless Steel Type 316 exhibits very high levels of corrosion resistance when compared to most other stainless-steel types. It has a slightly higher strength than Type 304 and can handle higher temperatures. In most cases, Type 316 is used for all exterior applications where relatively high strengths and high resistance to oxidation or eroding is required. In its bare state, Type 316 has a lustrous metallic finish. Stainless Steel Type 316 conforms to ASTM standards and is available in a wide variety of wire gauges.

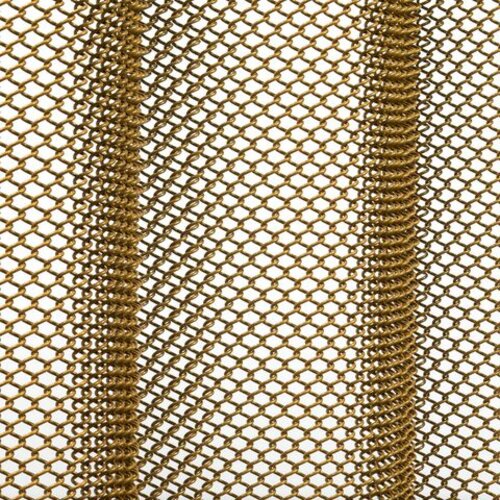

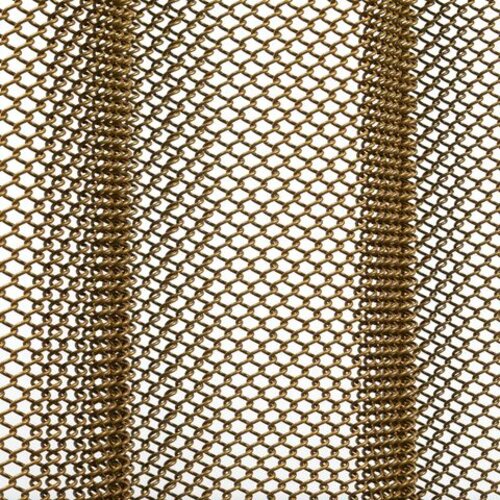

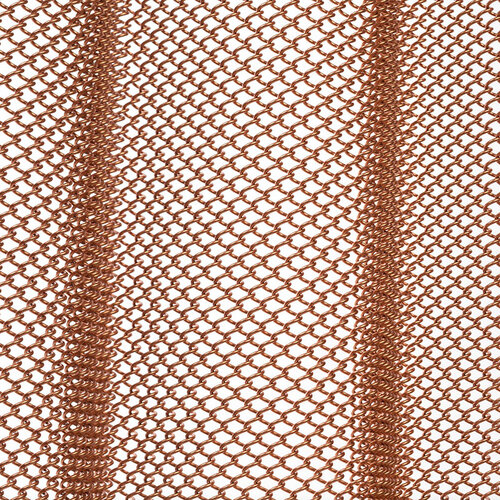

Copper-Clad Steel

Copper-Clad Steel Wire is our mild steel wire with pure copper metallurgically bonded to the low carbon steel wire’s surface. The Copper-Clad Wire exhibits a brilliant red polished finish when extruded in the continuous solid-cladding process. However, if left bare and untreated the wire’s appearance will slowly change to brownish hues and ultimately a grey/green patina. Additionally, left in its natural form Copper-Clad Steel Fabricoil® is naturally antimicrobial resulting in increased public health safety but also increased durability and beautiful aesthetics. By applying a thin layer of clear automotive lacquer, the bright salmon color can be maintained if desired. Our Copper-Clad wire conforms to ASTM standards and has both interior and exterior applications. Copper-Clad Steel is available in a wide variety of wire gauges.

![]() Natural finish no powder coating.

Natural finish no powder coating.

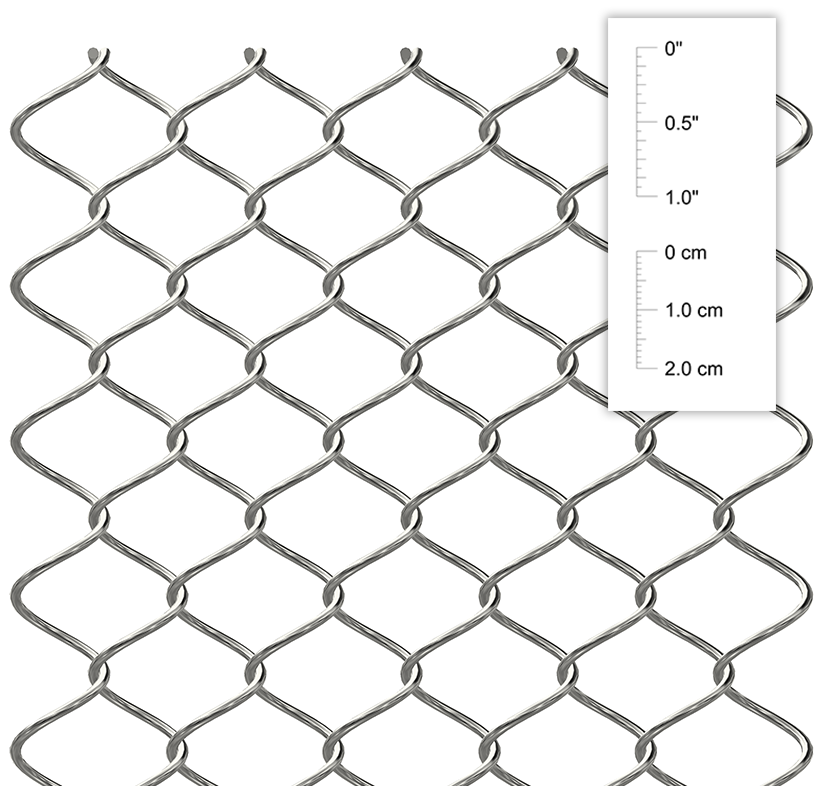

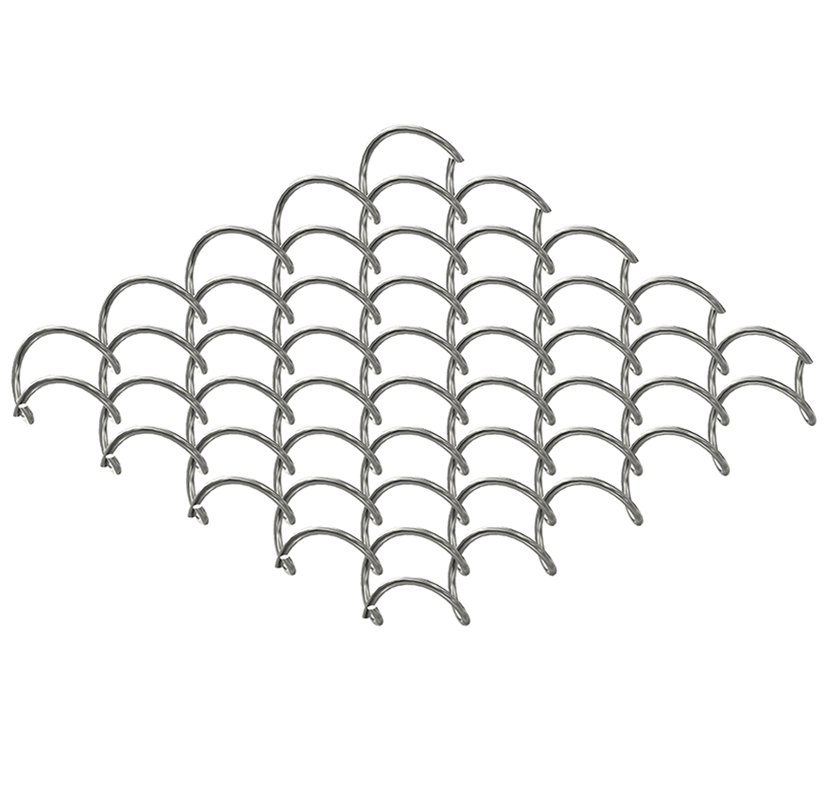

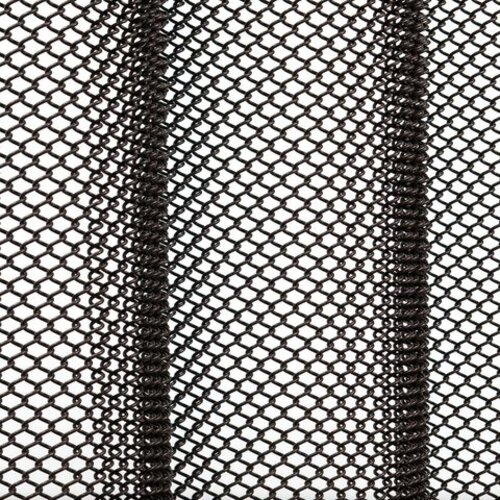

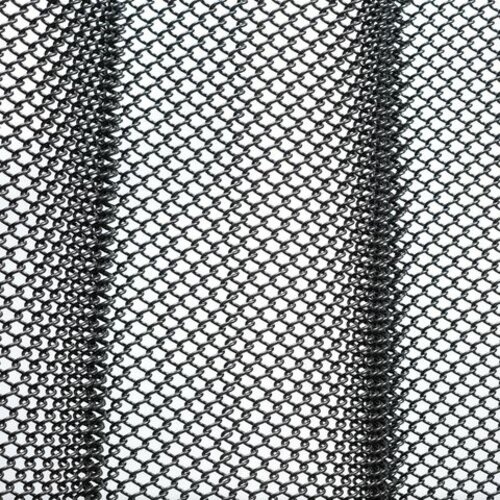

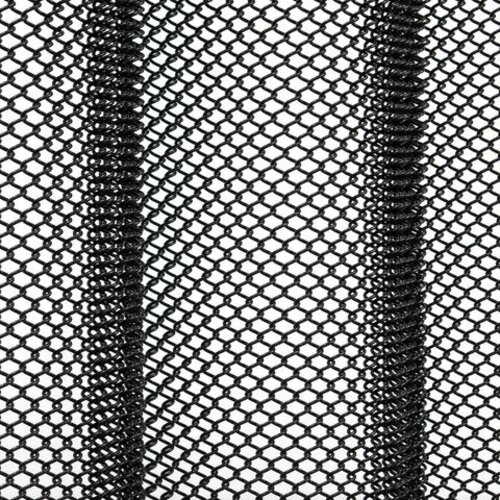

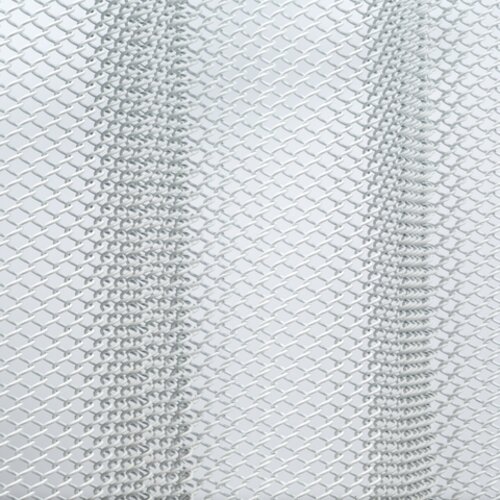

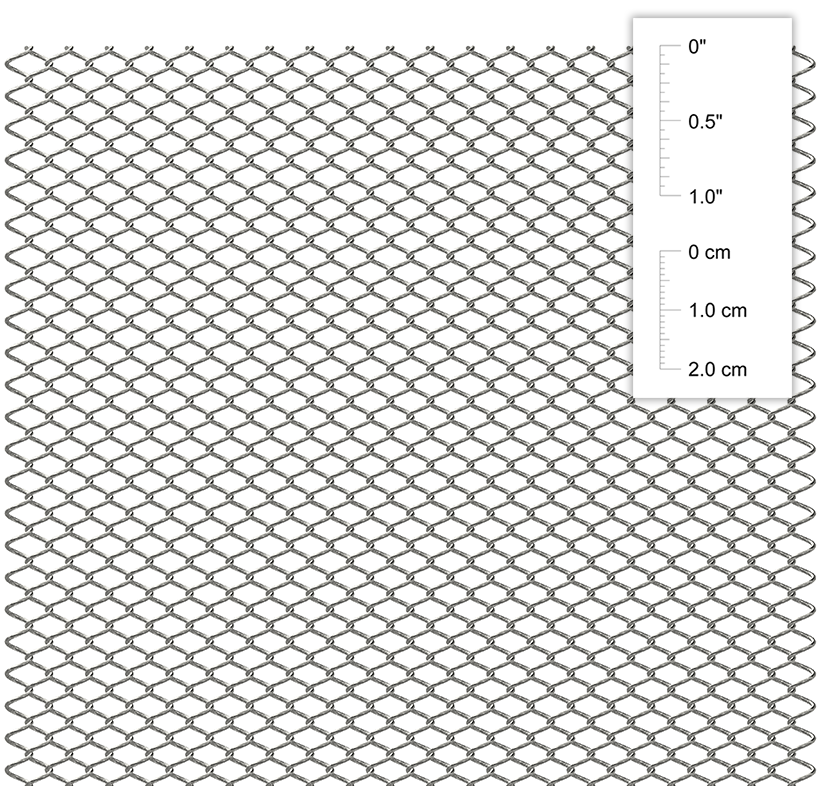

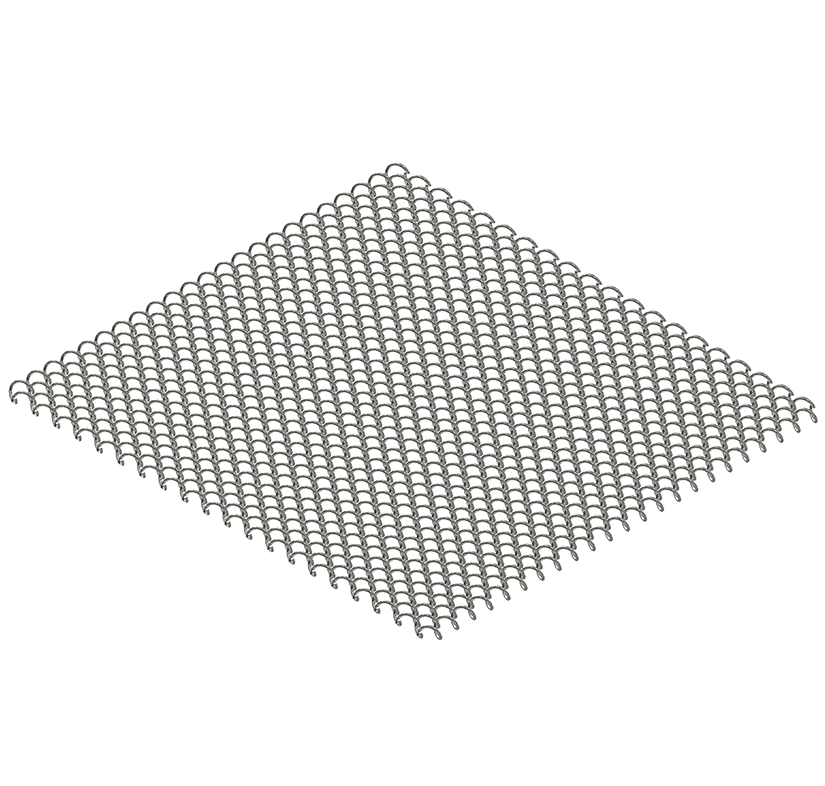

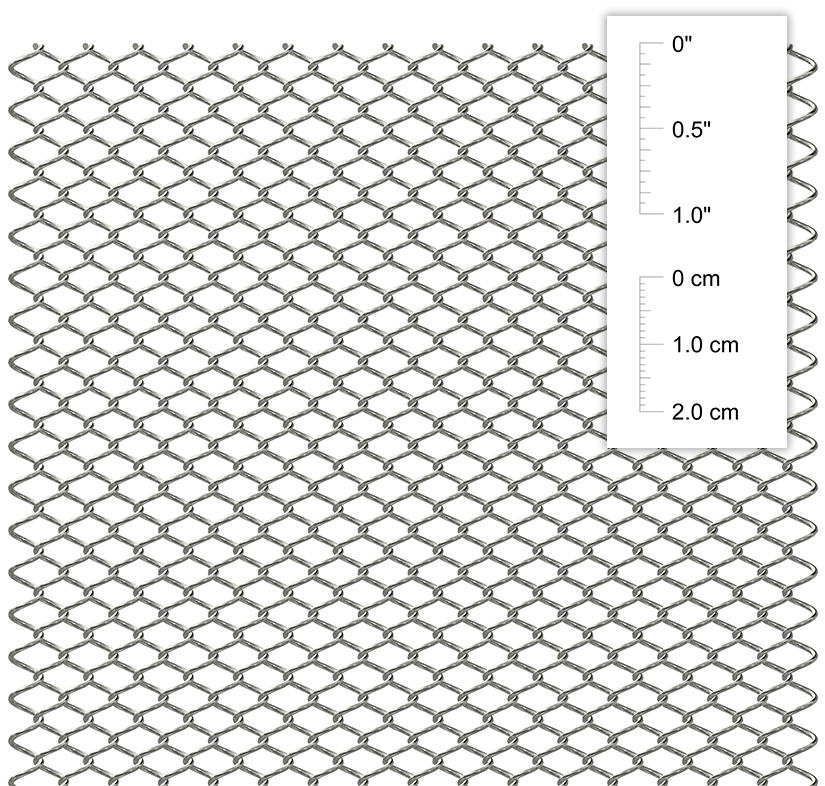

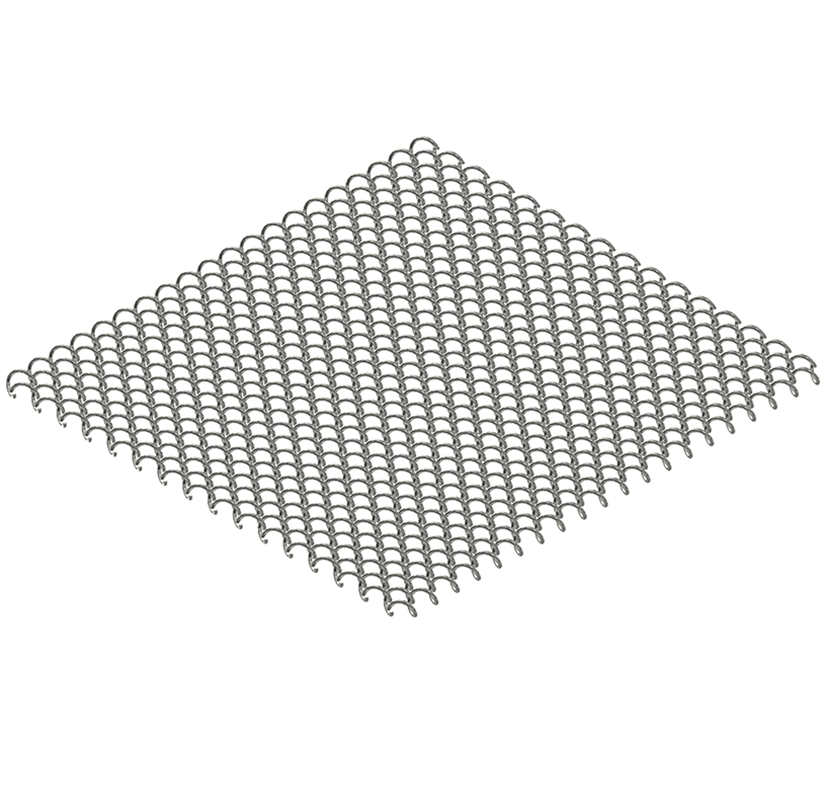

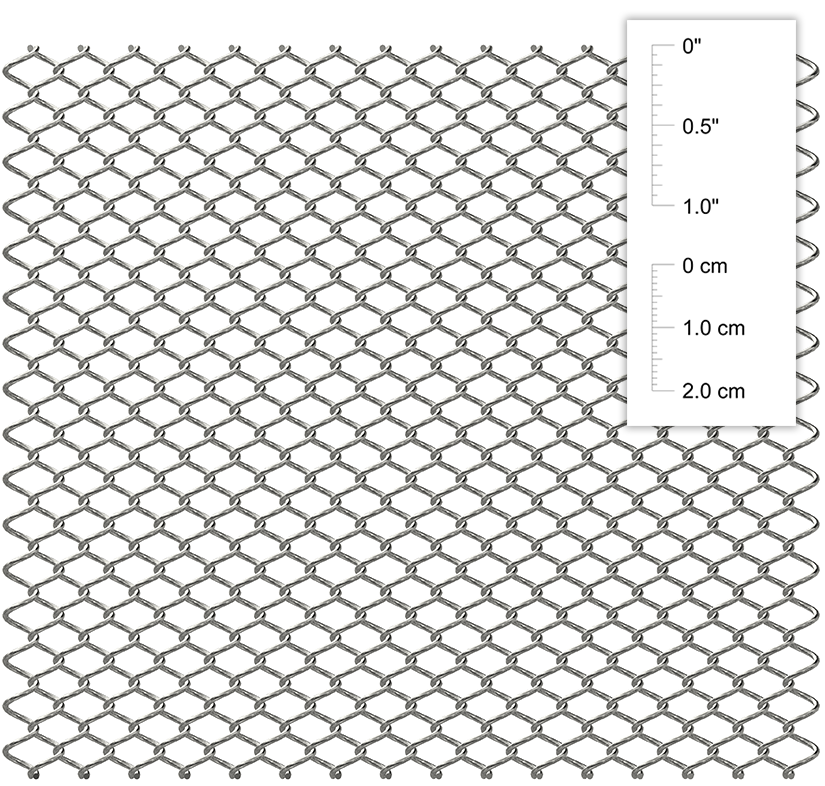

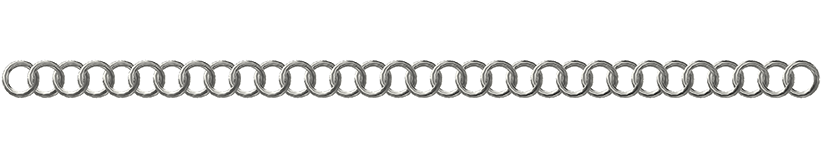

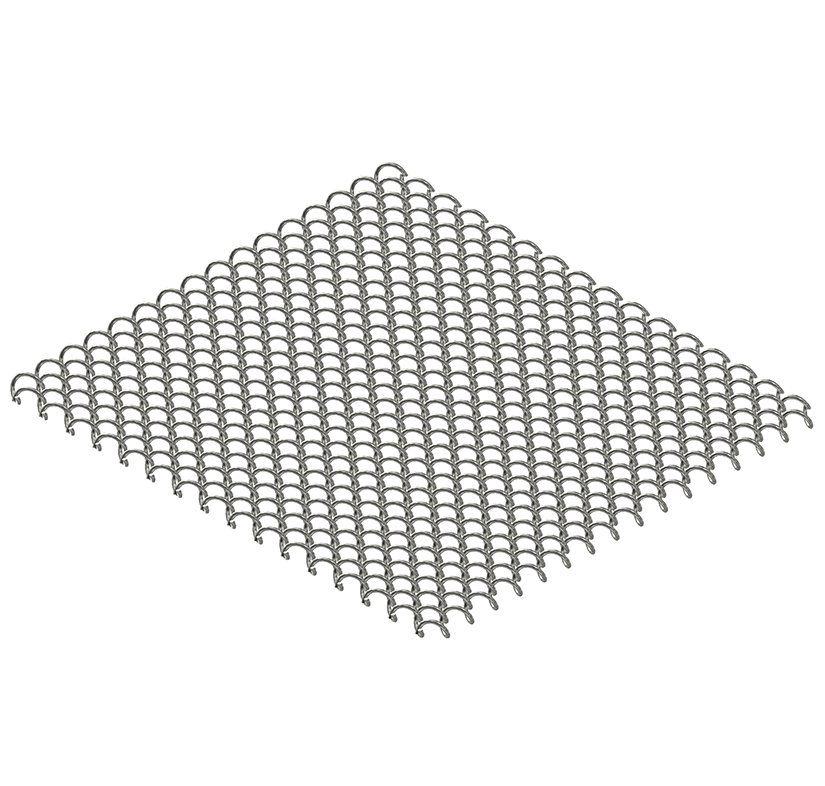

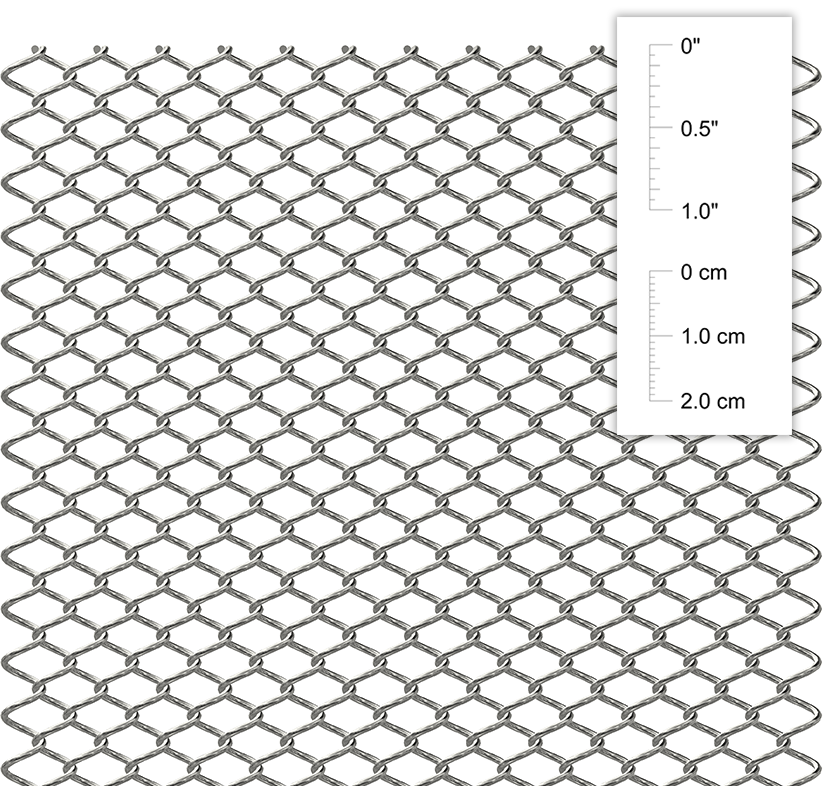

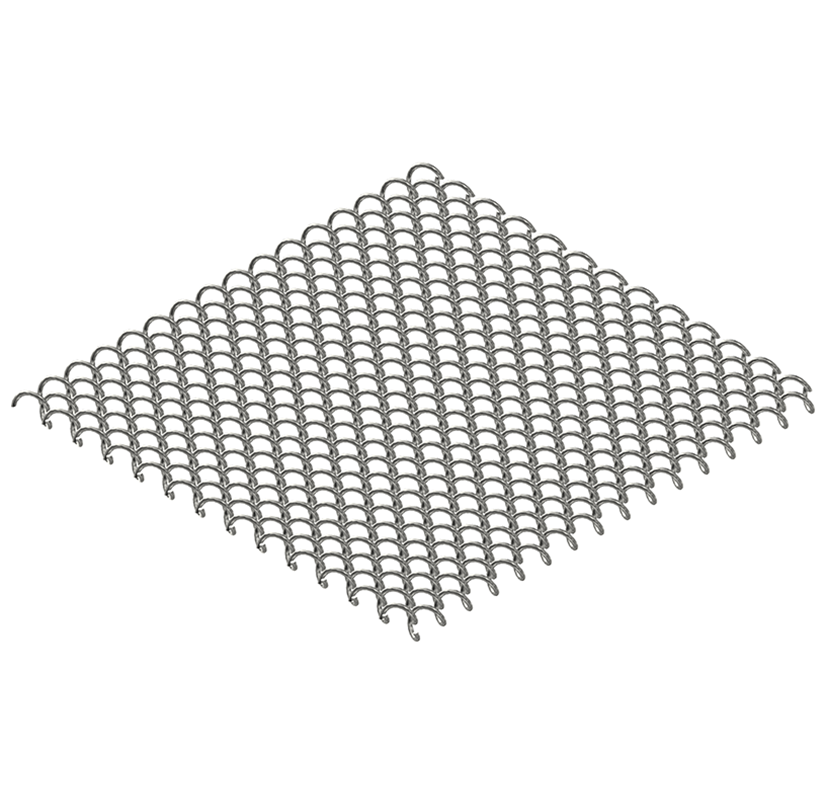

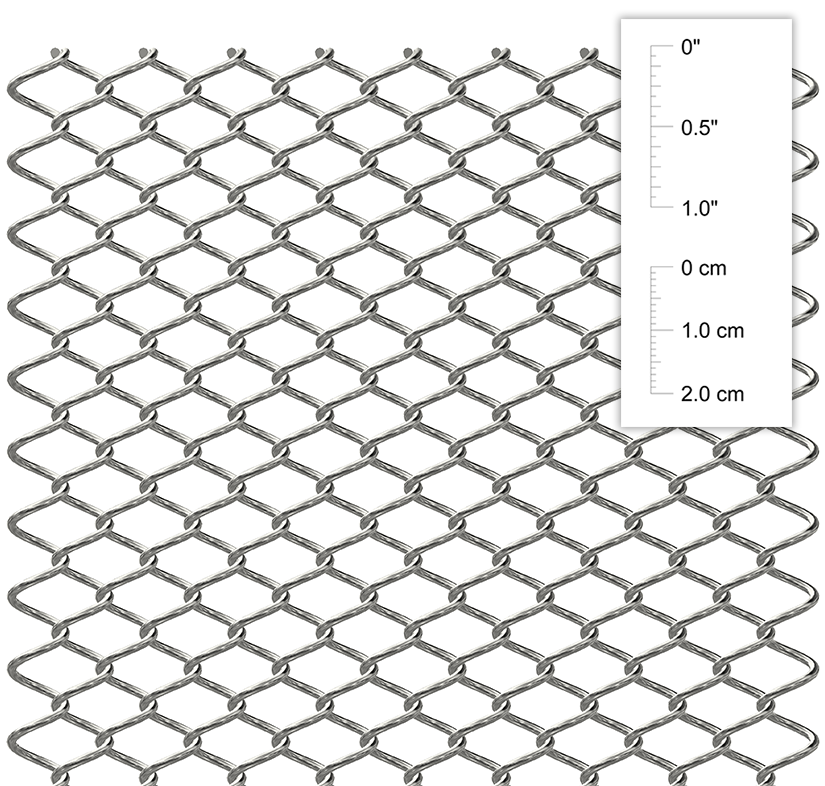

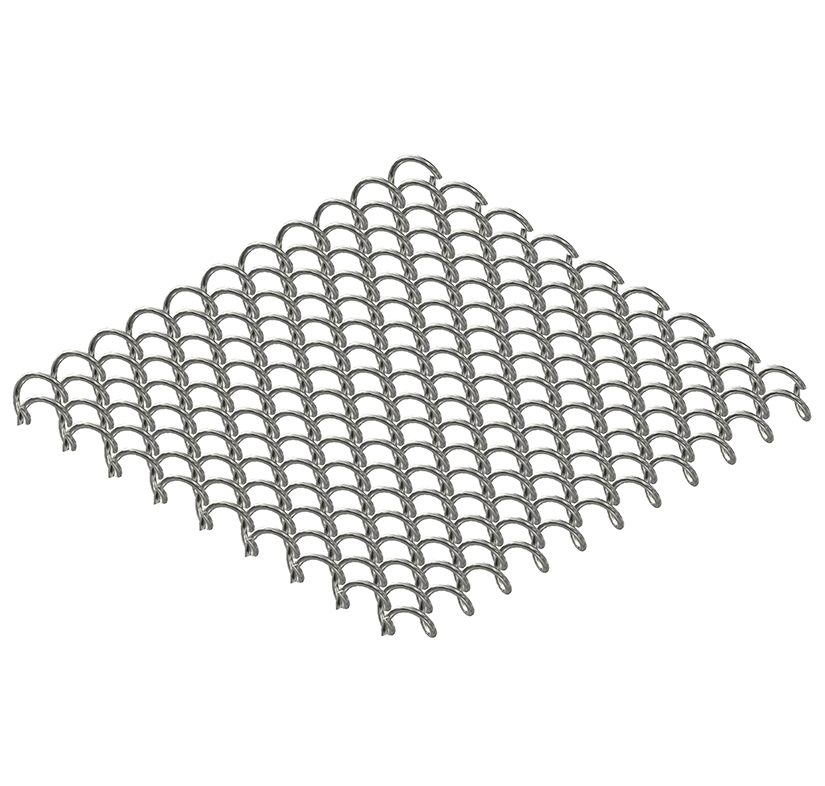

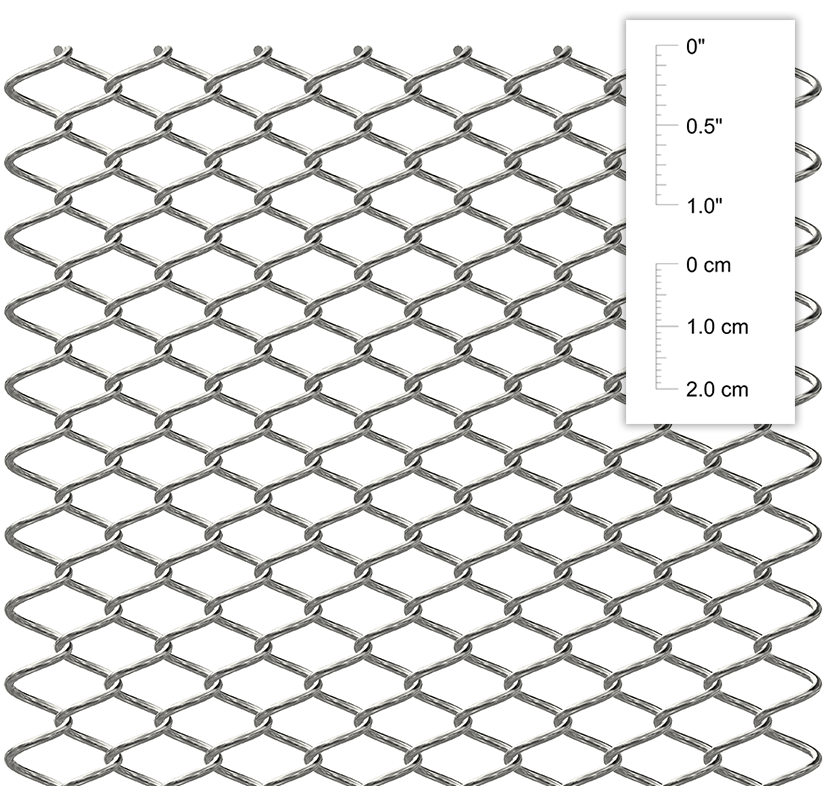

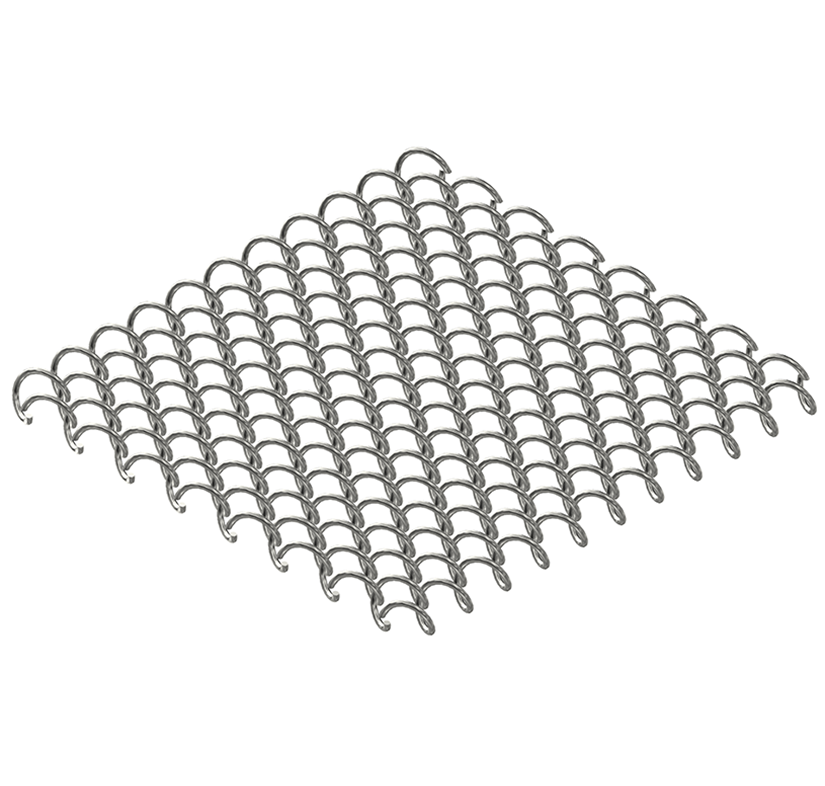

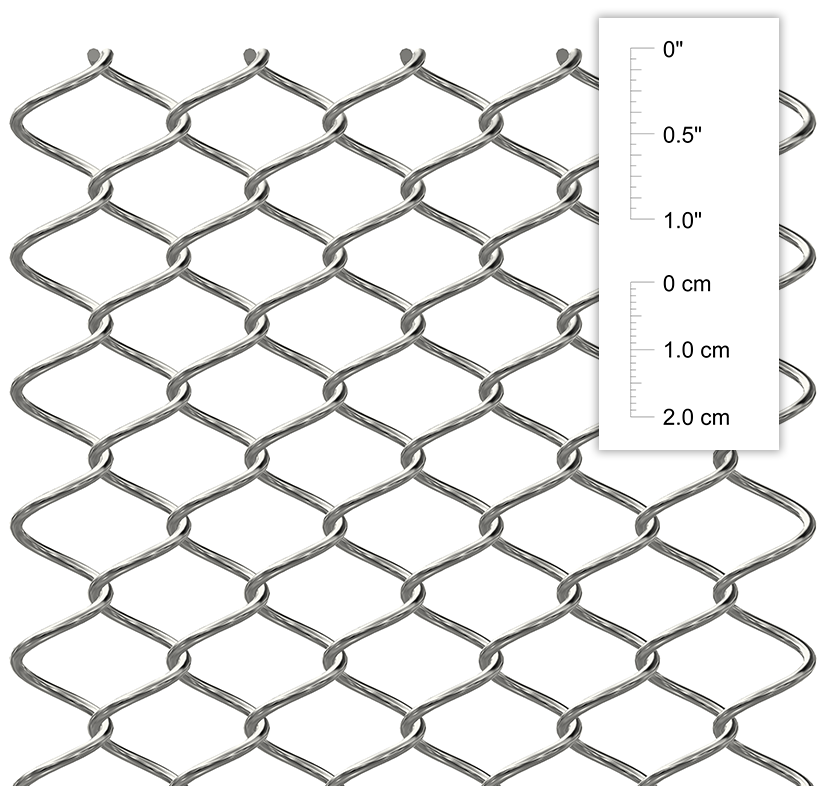

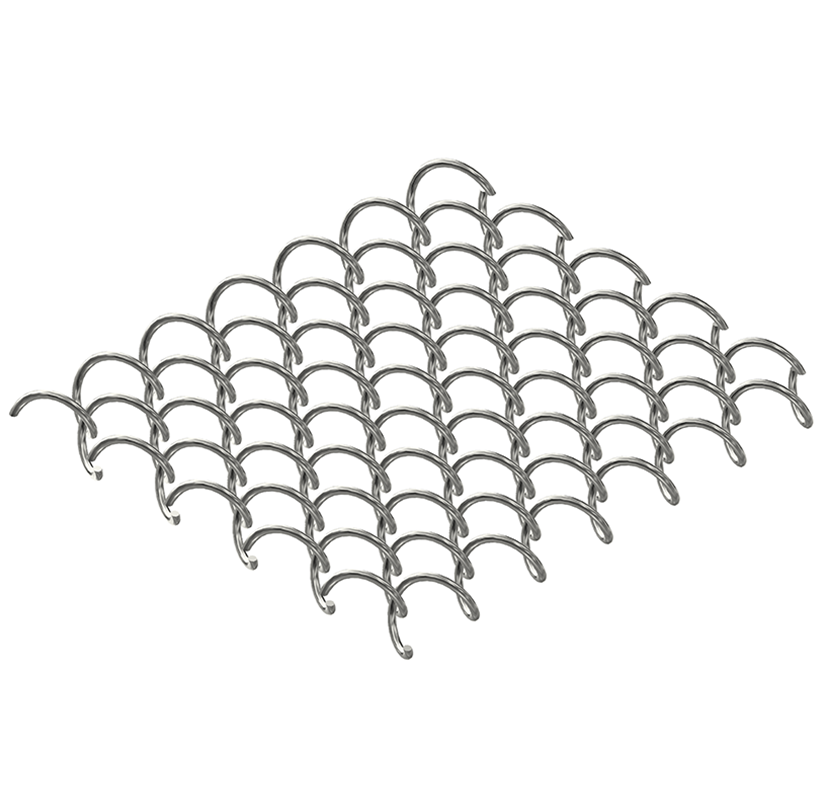

Weave Sizes for Exterior Fabricoil Coiled Wire Fabric System Applications

All Fabricoil® coiled wire fabric weaves share the same fundamental geometry created by interlocking individual strands of spiraled wire. What can vary widely through the weave size selected is SCALE which impacts the material’s percentage of open area (between 40% and 85%), thickness (between 3/32”and 1/2”), wire gauge (from 14 to 21), textured appearance, and strength of the material/system. The best approach to determining the optimal weave size and other specification options for your application is to collaborate with one of Cascade's experienced technical product specialists who can quickly guide you to selecting the perfect weave for your unique application based on performance requirements and design intent.

3/32"

1/8"

3/16"

1/4"

5/16"

3/8"

1/2"

5/8"